Abubuwan da suka shafi amfani da ƙarfe na asali

Don bincika matsala, da farko muna buƙatar sanin wasu ƙa'idodi na asali, waɗanda za su taimaka mana mu fahimta. Da farko, muna bukatar mu san ra'ayoyi biyu. Daya shi ne alternating magnetization, wanda, a takaice, ya faru a cikin baƙin ƙarfe core na wani Transformer da kuma a stator ko rotor hakora na mota; Ɗayan ita ce kaddarorin maganadisu na jujjuyawar, wanda aka samar ta hanyar stator ko rotor Yoke na motar. Akwai labarai da yawa waɗanda ke farawa daga maki biyu kuma suna lissafin asarar ƙarfe na motar bisa ga halaye daban-daban bisa ga hanyar mafita ta sama. Gwaje-gwaje sun nuna cewa zanen karfe na silicon yana nuna abubuwan da suka faru a ƙarƙashin magnetization na kaddarorin biyu:

Lokacin da ƙarfin maganadisu ya kasance ƙasa da 1.7 Tesla, asarar hysteresis da aka yi ta hanyar jujjuya maganadisu ya fi wanda ya haifar da sauyawar maganadisu; Lokacin da ya fi 1.7 Tesla, akasin haka gaskiya ne. Matsakaicin ƙarfin maganadisu na karkiyar motar gabaɗaya tsakanin 1.0 da 1.5 Tesla, kuma madaidaicin jujjuyawar jujjuyawar jujjuyawar maganadisu shine kusan 45 zuwa 65% fiye da madaidaicin asarar hysteresis magnetization.

Tabbas, ana amfani da abubuwan da suka gabata, kuma ban tabbatar da su da kaina ba a aikace. Bugu da kari, idan filin maganadisu da ke cikin core iron core ya canza, sai a shigar da wani wuta a cikinsa, wanda ake kira eddy current, kuma asarar da ta haifar ana kiransa hasara mai yawa. Domin rage hasara na yanzu, ƙarfin ƙarfen motar yawanci ba za a iya yin shi gabaɗaya ba, kuma ana lissafta shi axially ta zanen gadon ƙarfe da aka keɓe don hana kwararar igiyoyin ruwa. Ƙididdigar ƙididdiga ta musamman don amfani da ƙarfe ba zai zama da wahala a nan ba. Asalin dabara da mahimmancin lissafin amfani da ƙarfe na Baidu zai bayyana sarai. Mai zuwa shine nazarin mahimman abubuwa da yawa waɗanda ke shafar amfaninmu na ƙarfe, ta yadda kowa zai iya gaba ko baya ya cire matsalar a aikace-aikacen injiniyan aiki.

Bayan tattauna abubuwan da ke sama, me yasa masana'antar tambarin ke shafar amfani da ƙarfe? Halayen tsarin Punching galibi suna dogara da siffofi daban-daban na injunan garkuwar ramuka da tsinkaye, don ta tabbatar da yanayin wuraren damuwa da ke kusa da yanayin lamenation. Saboda alaƙar da ke tsakanin zurfin da siffa, sau da yawa yakan shafi kusurwoyi masu kaifi, har ma da yawan matakan damuwa na iya haifar da asarar ƙarfe mai mahimmanci a cikin yankunan da ba su da zurfi, musamman a cikin ƙananan gefuna masu tsayi a cikin kewayon lamination. Musamman, yana faruwa ne a cikin yankin alveolar, wanda sau da yawa yakan zama mayar da hankali ga bincike a cikin ainihin tsarin bincike. Ƙananan asara silicon karfe zanen gado sau da yawa ana ƙaddara da girma hatsi masu girma dabam. Tasiri na iya haifar da burbushin roba da tsagewar tsagewa a gefen kasan takardar, kuma kusurwar tasiri na iya yin tasiri mai mahimmanci akan girman burrs da nakasa. Idan babban yanki na damuwa ya shimfiɗa tare da yanki na lalacewa zuwa cikin kayan ciki, tsarin hatsi a cikin waɗannan wuraren ba makawa za su sami sauye-sauye masu dacewa, a murƙushe su ko fashe, kuma matsananciyar tsawo na iyaka zai faru tare da jagorancin tsagewa. A wannan lokacin, yawan iyakar hatsi a cikin yankin damuwa a cikin jagorancin shear zai karu ba makawa, wanda zai haifar da karuwar asarar ƙarfe a cikin yankin. Don haka, a wannan lokaci, ana iya ɗaukar kayan da ke cikin yankin damuwa a matsayin babban hasara wanda ya fadi a saman lamination na yau da kullum tare da tasirin tasiri. Ta wannan hanyar, ana iya ƙayyade ainihin ainihin abin da ke gefen gefen, kuma za'a iya ƙaddamar da ainihin asarar tasirin tasirin ta amfani da samfurin asarar ƙarfe.

1.Tasirin Tsara Tsara Akan Rashin Qarfe

Yanayin tasiri na asarar baƙin ƙarfe galibi suna kasancewa a cikin ɓangaren silin karfe na siliki, kuma matsalolin inji da na zafi zai shafi zanen ƙarfe na silicon tare da canje-canje a ainihin halayen su. Ƙarin damuwa na inji zai haifar da canje-canje a cikin asarar ƙarfe. A lokaci guda, ci gaba da karuwa a cikin zafin jiki na motar zai kuma inganta abubuwan da ke faruwa na asarar ƙarfe. Ɗaukar matakai masu tasiri don cire ƙarin damuwa na inji zai yi tasiri mai tasiri akan rage asarar ƙarfe a cikin motar.

2.Dalilan asarar hasara mai yawa a cikin hanyoyin masana'antu

Silicon karfe zanen gado, a matsayin babban Magnetic abu ga Motors, da gagarumin tasiri a kan aikin da mota saboda su yarda da zane da bukatun. Bugu da ƙari, aikin zanen gadon ƙarfe na silicon na daraja ɗaya na iya bambanta daga masana'antun daban-daban. Lokacin zabar kayan, yakamata a yi ƙoƙari don zaɓar kayan daga masana'antun ƙarfe masu kyau na silicon. A ƙasa akwai wasu mahimman abubuwa waɗanda a zahiri sun shafi shan ƙarfe waɗanda aka ci karo da su a baya.

Ba a killace takardar karfen silicon ko kuma a kula da shi yadda ya kamata. Irin wannan matsala za a iya gano a lokacin gwajin gwajin silicon karfe zanen gado, amma ba duk da mota masana'antun ne da wannan gwajin abu, da kuma sau da yawa wannan matsala ba a gane da kyau a cikin mota masana'antun.

Lalacewar rufi tsakanin zanen gado ko gajerun da'ira tsakanin zanen gado. Irin wannan matsala yana faruwa a lokacin aikin masana'antu na ƙarfe na ƙarfe. Idan matsa lamba a lokacin lamination na ƙarfe na ƙarfe ya yi yawa, yana haifar da lalacewa ga rufin tsakanin zanen gado; Ko kuma idan burbushin ya yi girma sosai bayan bugawa, ana iya cire su ta hanyar gogewa, wanda ke haifar da mummunar lalacewa ga rufin saman naushi; Bayan an gama lamination na baƙin ƙarfe, tsagi ba shi da santsi, kuma ana amfani da hanyar yin rajista; A madadin, saboda dalilai kamar rashin daidaituwa na stator bore da rashin daidaituwa tsakanin stator bore da leɓen kujerar inji, ana iya amfani da juyawa don gyarawa. Yin amfani da na yau da kullun na waɗannan hanyoyin samar da motoci da sarrafa su na da tasiri sosai kan aikin injin, musamman asarar ƙarfe.

Lokacin amfani da hanyoyi kamar ƙonawa ko dumama da wutar lantarki don tarwatsa iskar, yana iya haifar da ɗigon ƙarfe ya yi zafi, yana haifar da raguwar haɓakar maganadisu da lalacewa ga rufin da ke tsakanin zanen gado. Wannan matsalar ta fi faruwa ne a lokacin gyaran iskar gas da injina yayin aikin samarwa da sarrafawa.

Stacking walda da sauran matakai kuma na iya haifar da lahani ga rufin da ke tsakanin rijiyoyin, yana kara hasarar da ake yi a halin yanzu.

Rashin isassun nauyin ƙarfe da ƙarancin cikawa tsakanin zanen gado. Sakamakon ƙarshe shine cewa nauyin ƙarfe na ƙarfe bai isa ba, kuma sakamakon da ya fi dacewa shine cewa halin yanzu ya wuce juriya, yayin da akwai yiwuwar cewa asarar ƙarfe ta wuce misali.

Rufe kan takardar karfen silicon ya yi kauri sosai, yana haifar da da'irar maganadisu ta zama cikakke sosai. A wannan lokacin, lanƙwasa dangantakar dake tsakanin no-load current da ƙarfin lantarki yana lanƙwasa sosai. Wannan kuma shine maɓalli mai mahimmanci a cikin samarwa da sarrafa kayan aikin siliki.

A lokacin samarwa da sarrafa kayan ƙarfe na ƙarfe, daidaitawar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta za ta iya lalacewa ta lalacewa da kuma abin da aka makala mai sassauƙa, wanda zai haifar da karuwa a cikin asarar baƙin ƙarfe a ƙarƙashin induction guda ɗaya; Don injunan mitar mitoci, ƙarin asarar baƙin ƙarfe da ke haifar da jituwa ya kamata kuma a yi la'akari da su; Wannan lamari ne da ya kamata a yi la'akari da shi sosai a cikin tsarin ƙira.

Bugu da ƙari, abubuwan da ke sama, ƙimar ƙira na asarar ƙarfe ya kamata ya dogara ne akan ainihin samarwa da sarrafa kayan ƙarfe, kuma a yi ƙoƙari don tabbatar da cewa ƙimar ka'idar ta dace da ainihin ƙimar. Halayen lanƙwasa da masu samar da kayan gabaɗaya suka bayar ana auna su ta amfani da hanyar coil square Epstein, amma yanayin maganadisu na sassa daban-daban a cikin motar ya bambanta, kuma wannan asarar ƙarfe ta musamman ba za a iya la'akari da ita a halin yanzu ba. Wannan na iya haifar da bambance-bambancen matakan rashin daidaituwa tsakanin ƙididdiga da ƙididdiga masu ƙima.

Hanyoyi don rage asarar ƙarfe a cikin ƙirar injiniya

Akwai hanyoyi da yawa don rage amfani da ƙarfe a aikin injiniya, kuma abu mafi mahimmanci shine daidaita magungunan zuwa yanayin. Tabbas, ba batun shan ƙarfe ba ne kawai, har ma da sauran hasara. Hanya mafi mahimmanci ita ce sanin dalilan babban asarar ƙarfe, kamar babban ƙarfin maganadisu, babban mitar, ko yawan saturation na gida. Tabbas, a cikin hanyar al'ada, a gefe guda, wajibi ne a kusanci gaskiya kamar yadda zai yiwu daga gefen simulation, kuma a gefe guda, tsarin yana haɗuwa da fasaha don rage ƙarin amfani da ƙarfe. Hanyar da aka fi amfani da ita ita ce ƙara amfani da zanen siliki mai kyau, kuma ba tare da la'akari da farashi ba, ana iya zaɓar babban siliki na karfe da aka shigo da shi. Tabbas, haɓaka sabbin fasahohin makamashi na cikin gida ya kuma haifar da ingantacciyar ci gaba a sama da ƙasa. Hakanan masana'antar ƙarfe na cikin gida suna ƙaddamar da samfuran ƙarfe na musamman na silicon. Asalin asali yana da kyakkyawan rarrabuwa na samfuran don yanayin aikace-aikacen daban-daban. Anan ga wasu hanyoyi madaidaiciya don saduwa da su:

1. Haɓaka kewayawar maganadisu

Haɓaka da'irar maganadisu, don zama madaidaici, yana haɓaka sine na filin maganadisu. Wannan yana da mahimmanci, ba kawai ga ƙayyadaddun induction induction mitar ba. Motocin shigar da mitar mitoci da injinan aiki tare suna da mahimmanci. Lokacin da nake aiki a masana'antar kera masaku, na kera motoci biyu masu aiki daban-daban don rage farashi. Tabbas, abu mafi mahimmanci shine kasancewar ko rashi na sandunan skewed, wanda ya haifar da halayen sinusoidal marasa daidaituwa na filin magnetic ratar iska. Sakamakon yin aiki a cikin sauri mai sauri, asarar baƙin ƙarfe yana da adadi mai yawa, wanda ya haifar da babban bambanci a cikin asarar da ke tsakanin motocin biyu. A ƙarshe, bayan wasu ƙididdiga na baya, bambancin asarar baƙin ƙarfe na motar da ke ƙarƙashin tsarin sarrafawa ya karu da fiye da sau biyu. Wannan kuma yana tunatar da kowa don haɗa algorithms sarrafawa lokacin sake yin canjin mitar sarrafa injuna.

2.Reduce Magnetic yawa

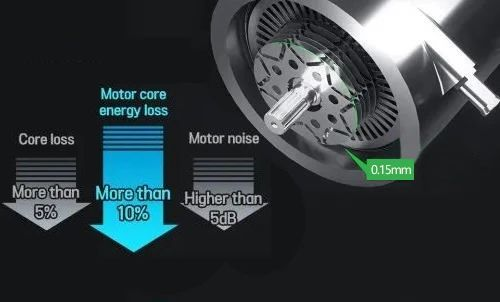

Ƙara tsayin ƙarfe na ƙarfe ko haɓaka yanki na maganadisu na maganadisu don rage yawan ƙarfin maganadisu, amma adadin baƙin ƙarfe da ake amfani da shi a cikin motar yana ƙaruwa daidai da haka;

3.Rage kauri daga kwakwalwan ƙarfe don rage asarar da aka haifar

Maye gurbin zafi-birgima silicon karfe zanen gado tare da sanyi-birgima silicon karfe zanen gado iya rage kauri na silicon karfe zanen gado, amma bakin ciki baƙin ƙarfe kwakwalwan kwamfuta zai ƙara yawan baƙin ƙarfe kwakwalwan kwamfuta da kuma mota masana'antu halin kaka;

4.Adopting sanyi birgima silicon karfe zanen gado tare da mai kyau Magnetic conductivity don rage hysteresis asarar;

5.Adopting high-yi baƙin ƙarfe guntu rufi rufi;

6.Heat magani da fasahar kere kere

Ragowar damuwa bayan sarrafa kwakwalwan ƙarfe na iya yin tasiri sosai ga asarar motar. Lokacin sarrafa zanen karfe na silicon, jagorar yankewa da damuwa mai ƙarfi suna da tasiri mai mahimmanci akan asarar baƙin ƙarfe. Yanke tare da mirgina shugabanci na silicon karfe takardar da kuma gudanar da zafi magani a kan silicon karfe takardar iya rage asara da 10% zuwa 20%.

Lokacin aikawa: Nov-01-2023