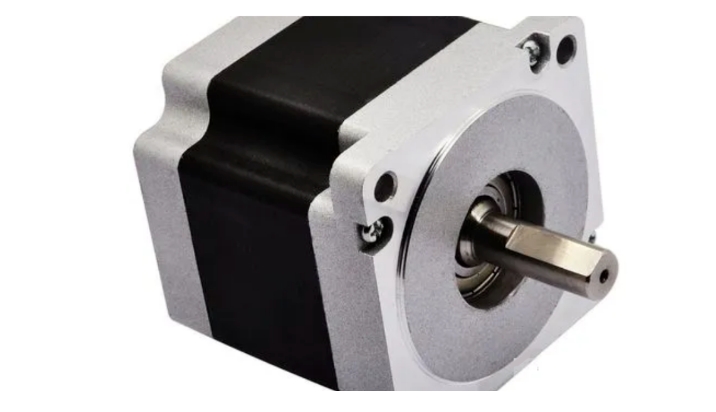

1. Dalilin da yasa aka sanya wa injin stepper na'urar rage zafi

Mitar sauya yanayin yanayin stator a cikin motar stepper, kamar canza bugun shigarwa na da'irar tuƙin motar stepper don sa ta motsa a ƙaramin gudu. Lokacin da motar stepper mai ƙarancin gudu ke jiran umarnin stepper, rotor yana cikin yanayin tsayawa. Lokacin da take tafiya a ƙaramin gudu, canjin saurin zai yi yawa. Idan aka canza shi zuwa babban aiki, za a iya magance matsalar canjin gudu, amma ƙarfin juyi ba zai isa ba. Ƙaramin gudu zai haifar da canjin juyi, yayin da babban gudu zai haifar da rashin isasshen ƙarfin juyi, don haka ana buƙatar mai rage gudu.

2. Menene na'urorin rage yawan amfani da injinan stepper?

Mai rage aiki wani abu ne mai zaman kansa wanda ya ƙunshi watsa gear, watsa tsutsotsi, da watsa tsutsotsi a cikin harsashi mai tauri. Ana amfani da shi azaman na'urar watsawa mai ragewa tsakanin na'urar asali da injin aiki, yana taka rawa wajen daidaita gudu da kuma juyi tsakanin na'urar asali da injin aiki ko mai kunnawa;

Akwai nau'ikan na'urorin rage gudu daban-daban, waɗanda za a iya raba su zuwa na'urorin rage gudu, na'urorin rage tsutsotsi, da na'urorin rage gudu na duniya bisa ga nau'in na'urorin watsawa; Dangane da matakai daban-daban na watsawa, ana iya raba su zuwa na'urori masu rage gudu na mataki ɗaya da na'urori masu matakai da yawa;

Dangane da siffar giyar, ana iya raba su zuwa masu rage gear na silinda, masu rage gear na bevel, da kuma masu rage gear na bevel na silinda;

Dangane da tsarin watsawa, ana iya raba shi zuwa masu rage gudu da ba a buɗe ba, masu rage kwararar da aka raba, da masu rage gudu da coaxial.

Na'urorin rage gudu da aka sanya wa injinan stepper sun haɗa da na'urorin rage gudu na duniya, na'urorin rage gudu na tsutsotsi, na'urorin rage gudu na layi ɗaya, da na'urorin rage gudu na sukurori.

Menene daidaiton na'urar rage zafin duniya ta injin stepper?

Daidaiton na'urar ragewa, wanda aka fi sani da clearance na dawowa, ana cimma shi ta hanyar gyara ƙarshen fitarwa da juya shi a gefen agogo da akasin agogo don samar da karfin juyi mai ƙima na +-2% a ƙarshen fitarwa. Idan akwai ƙaramin motsi na kusurwa a ƙarshen shigarwar na'urar ragewa, ana kiran wannan motsi na kusurwar clearance na dawowa. Naúrar ita ce "minti na arc", wanda shine kashi ɗaya cikin sittin na digiri. Matsakaicin ƙimar clearance na dawowa yana nufin ƙarshen fitarwa na akwatin gear.

Na'urar rage girman injin stepper tana da halaye na tauri mai yawa, daidaito mai yawa (har zuwa maki 1 a kowane mataki), ingantaccen watsawa mai yawa (97% -98% a kowane mataki), babban rabon karfin juyi/girma, kuma babu kulawa.

Ba za a iya daidaita daidaiton watsawa na motar stepper ba, kuma kusurwar aiki na motar stepper ana tantance ta gaba ɗaya ta tsawon matakin da lambar bugun. Ana iya ƙirga lambar bugun gaba gaba ɗaya, kuma babu wata ma'ana ta daidaito a cikin adadi na dijital. Mataki ɗaya mataki ɗaya ne, mataki na biyu kuma matakai biyu ne.

Daidaiton da aka inganta a halin yanzu shine daidaiton dawo da gear na gearbox na rage girman duniya:

1. Hanyar daidaita daidaiton sandar:

Daidaita daidaiton juyawar spindle mai rage girman duniya gabaɗaya yana ƙayyade ta hanyar bearing idan kuskuren injin na spindle da kansa ya cika buƙatun.

Mabuɗin daidaita daidaiton juyawar sandar shine daidaita daidaiton juyawar sandar. Kula da daidaiton juyawar sandar yana da mahimmanci ga aiki da tsawon rayuwar sassan sandar.

Ga bearings na birgima, idan akwai babban gibi, nauyin ba wai kawai zai ta'allaƙa ne kan abin birgima a alkiblar ƙarfi ba, har ma zai haifar da babban yawan damuwa a lokacin da aka haɗu tsakanin hanyoyin tsere na ciki da na waje na bearing, ya rage tsawon lokacin ɗaukar kaya, kuma ya karkatar da tsakiyar sandar, wanda hakan yana da sauƙin haifar da girgizar sassan spindle.

Saboda haka, dole ne a fara loda gyaran bearings ɗin da ke birgima don samar da wani adadin tsangwama a cikin bearings ɗin, ta haka ne za a samar da wani adadin nakasu na roba a lokacin da abin da ke birgima da hanyoyin tsere na ciki da na waje ke haɗuwa, ta haka ne za a inganta taurin bearings ɗin.

2. Hanyar daidaita gibi:

Na'urar rage hasken duniya tana haifar da gogayya yayin motsi, wanda ke haifar da canje-canje a girman, siffa, da ingancin saman sassan, da kuma lalacewa, wanda ke haifar da ƙaruwar daidaito tsakanin sassan. A wannan lokacin, muna buƙatar daidaita shi cikin iyaka mai dacewa don tabbatar da daidaiton motsi tsakanin sassan.

3. Hanyar diyya ta kuskure:

Abin da ke haifar da gyara kurakuran sassan da kansu yayin aiki ta hanyar haɗa su yadda ya kamata don tabbatar da daidaiton hanyar motsi ta kayan aiki.

4. Cikakken hanyar diyya:

Yi amfani da kayan aikin da aka sanya a kan na'urar rage zafi don tabbatar da cewa an daidaita injin ɗin daidai kuma an daidaita shi a kan teburin aiki, domin kawar da cikakken sakamakon kurakurai daban-daban na daidaito.

Lokacin Saƙo: Nuwamba-28-2023