Theinjinshaft ɗin yana da rami, yana da kyakkyawan aikin watsa zafi kuma yana iya haɓaka nauyi mai sauƙiinjin.A da, sandunan mota galibi suna da ƙarfi, amma saboda amfani da sandunan mota, galibi damuwa tana kan saman sandunan, kuma damuwar da ke kan tsakiyar ba ta da yawa. Dangane da halayen lanƙwasawa da juyawa na kayan injiniya, ɓangaren ciki nainjinAn yi ramin ramin daidai gwargwado, kuma ƙaramin diamita na waje kawai ake buƙata don ƙara ɓangaren waje. Ramin ramin zai iya cika aiki da aikin da aka yi da sandar mai ƙarfi, amma nauyinsa na iya raguwa sosai. A halin yanzu, saboda ramin ramininjinA shaft, mai sanyaya zai iya shiga cikin shaft ɗin motar, yana ƙara yankin watsa zafi da kuma inganta ingancin watsa zafi. A ƙarƙashin yanayin caji mai sauri na 800V mai ƙarfi, fa'idar shaft ɗin motar mai rami ya fi girma. Hanyoyin samarwa na yanzu don shaft ɗin motar mai rami sun haɗa da ramin shaft mai ƙarfi, walda, da haɗakar siffa, waɗanda daga cikinsu ake amfani da walda da haɗakar siffa a cikin samarwa.

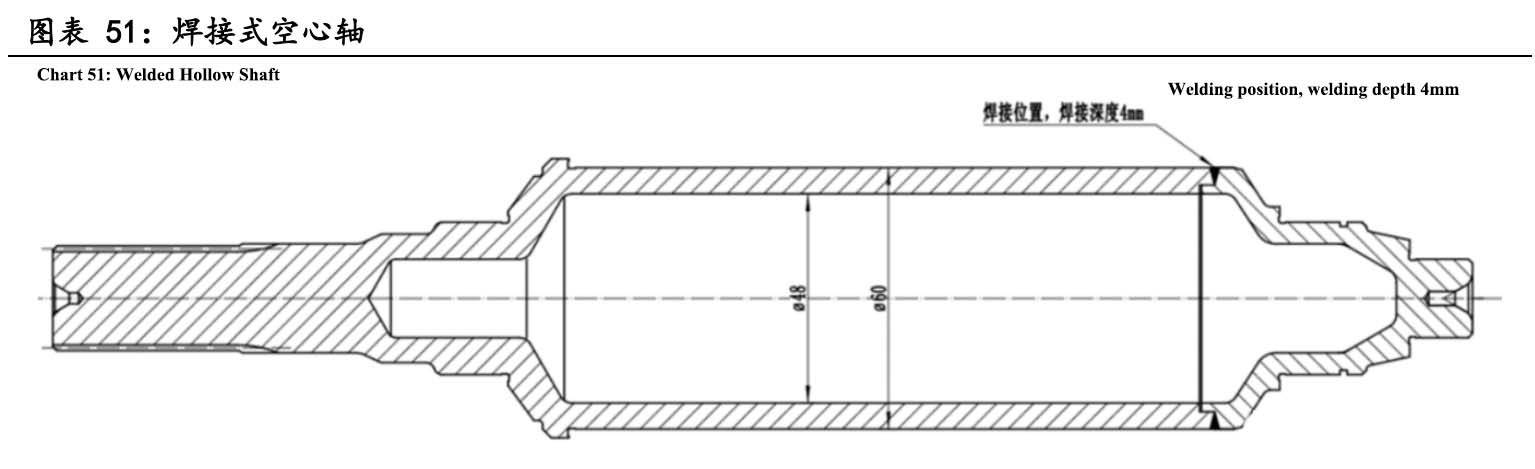

Ana samun ramin da aka haɗa da rami mai rami ta hanyar ƙera shi don cimma ramin ciki mai matakai na shaft, sannan a yi masa ƙera shi da kuma haɗa shi da siffa. Ta hanyar ƙera shi, ana kiyaye canje-canjen siffar ramin ciki tare da tsarin samfurin da buƙatun ƙarfi gwargwadon iko. Gabaɗaya, ana iya tsara kauri na asali na bango na samfurin a ƙasa da 5mm. Kayan aikin walda gabaɗaya suna ɗaukar walda mai fashewa ko walda mai laser. Idan an yi amfani da walda mai fashewa, matsayin haɗin gwiwa na butt gabaɗaya shine kusan fitowar walda 3mm. Ta amfani da walda mai laser, zurfin walda gabaɗaya yana tsakanin 3.5 zuwa 4.5mm, kuma ana iya tabbatar da ƙarfin walda ya fi 80% na substrate. Wasu masu samar da kayayyaki ma za su iya cimma sama da 90% na ƙarfin substrate ta hanyar tsauraran matakan sarrafa tsari. Bayan an kammala walda mai rami, ya zama dole a gudanar da gwajin ultrasonic ko X-ray akan ƙaramin tsari da ingancin walda na yankin walda don tabbatar da daidaiton samfurin.

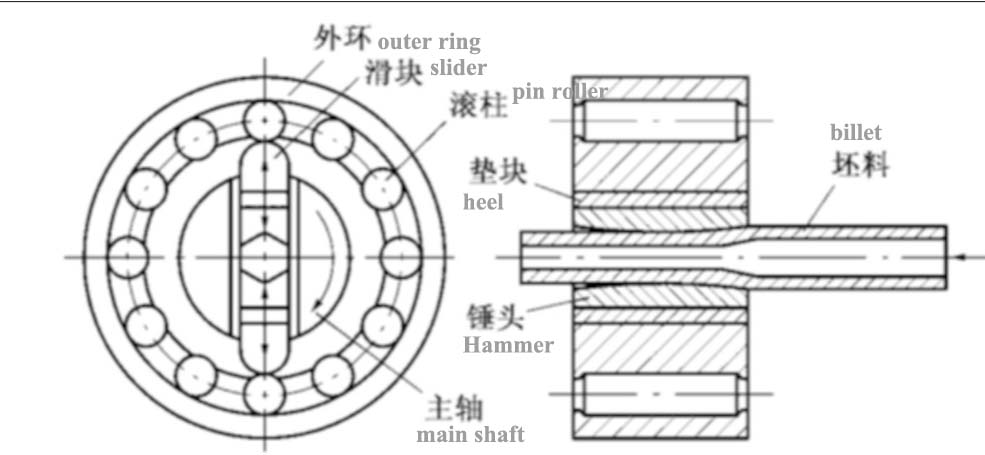

Kayan aiki na waje da ke kan fanko, galibi suna ƙera shaft ɗin da aka haɗa da rami mai zurfi, wanda hakan ke ba wa ɓangaren ciki damar cimma ramin ciki kai tsaye na shaft. A halin yanzu, ana amfani da radial forging da rotary forging, kuma galibi ana shigo da kayan aikin. radial forging abu ne na kayan aikin kamfanin FELLS, yayin da rotary forging abu ne na kayan aikin kamfanin GFM. Yawanci ana samun radial forging form ta hanyar amfani da guduma guda huɗu ko fiye masu daidaito a mita sama da 240 a minti ɗaya don cimma ƙaramin nakasu na bututun fanko da na kai tsaye. Rotary forging forming tsari ne na shirya kawunan guduma da yawa daidai gwargwado a cikin alkiblar billet. Kan guduma yana juyawa a kusa da axis yayin da yake yin radial high-mita forging akan workpiece, yana rage girman giciye na billet ɗin kuma yana faɗaɗa a axial don samun workpiece. Idan aka kwatanta da radial strong shafts, farashin kera shafts masu rami da aka haɗa zai ƙaru da kusan 20%, amma nauyin shafts ɗin mota gabaɗaya zai ragu da 30-35%.

Lokacin Saƙo: Satumba-15-2023